1. Photos

2. Assembly notes

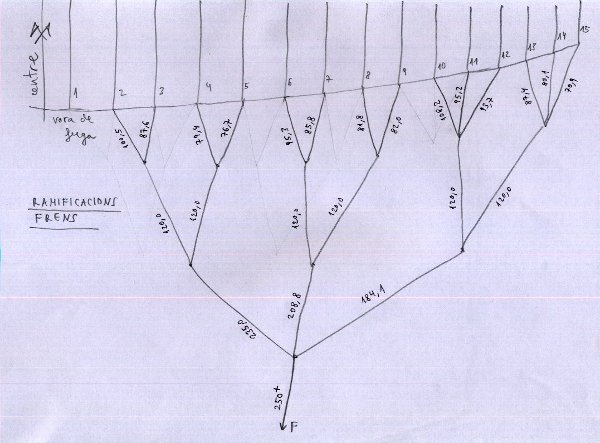

4. Lines

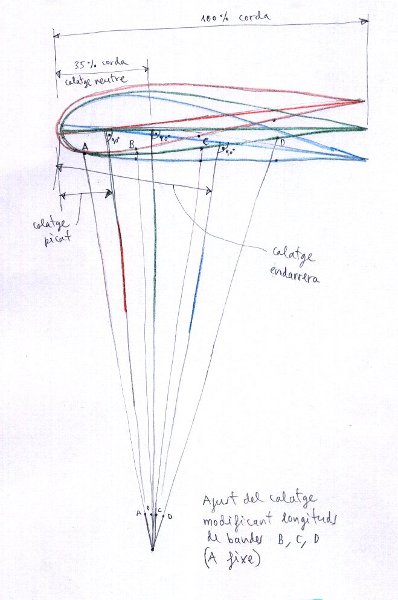

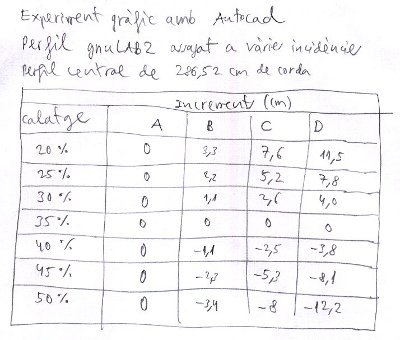

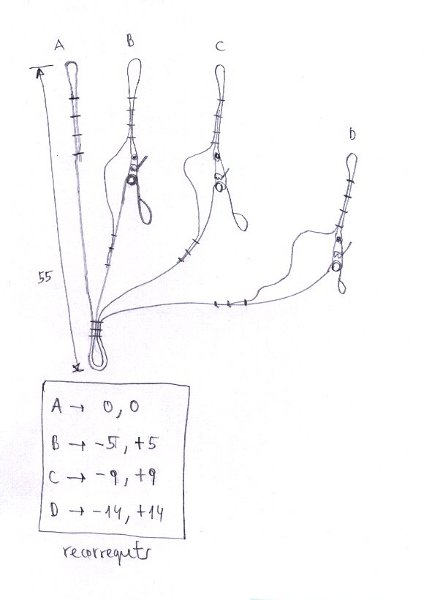

5. Risers

1. Photos

Training hill

2. Assembly notes

2. Assembly notes

4. Lines

5. Risers

1. Photos

Training hill

Ager

16-1-2011

The

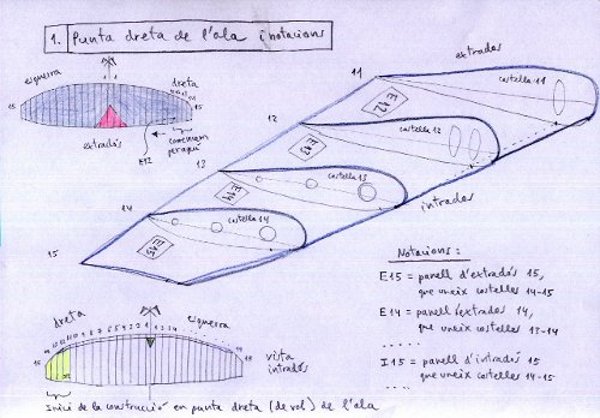

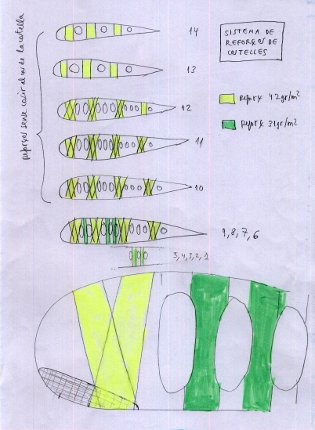

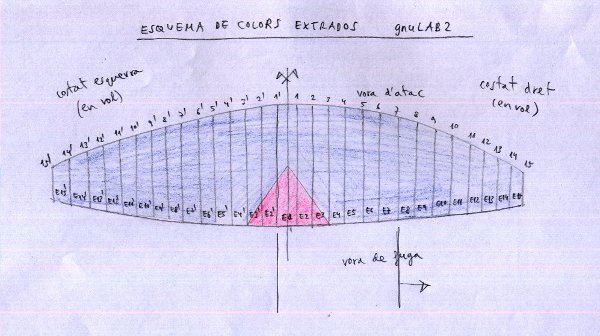

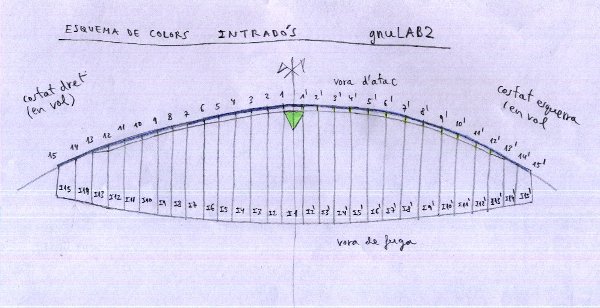

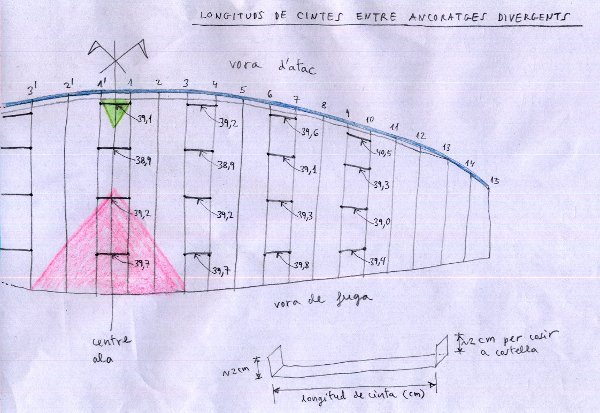

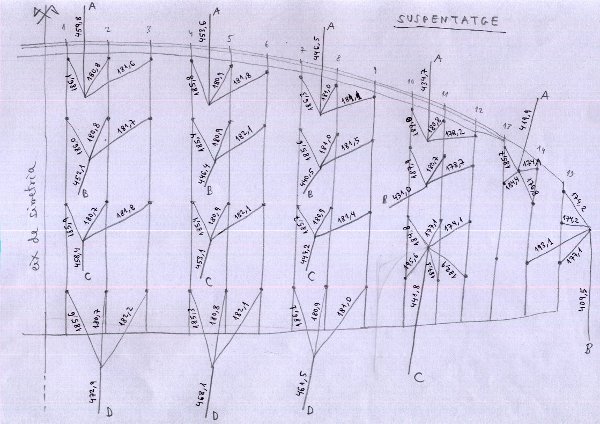

construction of this proto being so collaborative. The design. pattern

making, and cutting of the tissue is being done in Teià, in the Laboratory, and the

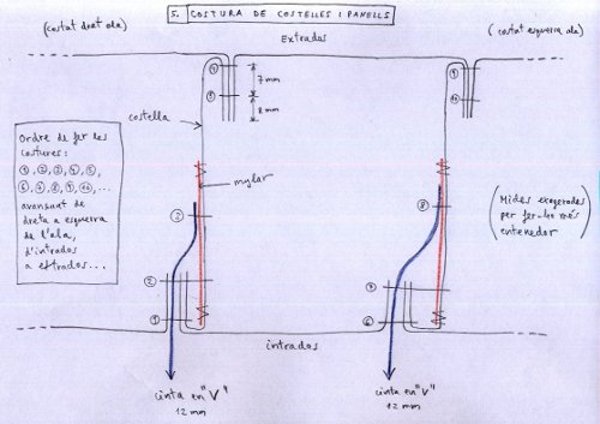

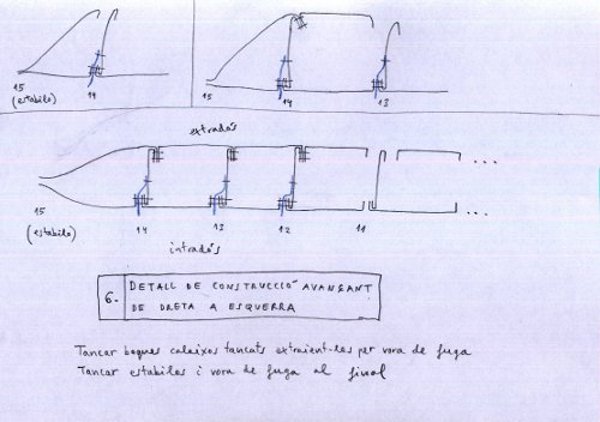

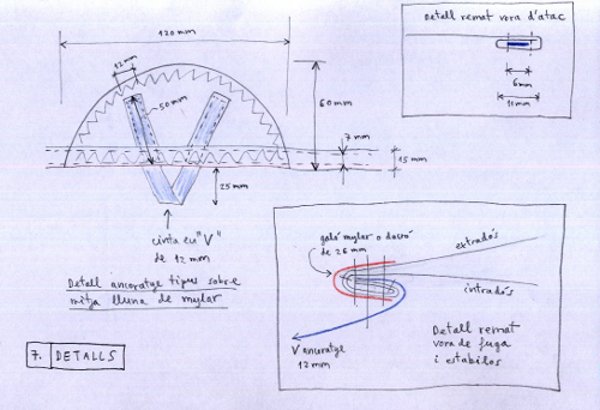

assembly of all panels, profiles, anchorages,

reinforcements, and the suspension lines, was being done in the

paragliding workshop STRIP-AIR

in El

Prat de Llobregat (Barcelona). The design and construction of a new

paraglider prototype is not easy and we must find the best synergies!

The cutting of the ripstop has been done with a soldering iron of 30W for electronics, with a sharp edge knife-shaped. We put the ripstop, above the template of the panels or ribs (template formed by the junction of A3 size sheets). The tracing was performed with ease by the transparency of the ripstop.The method has its advantages and disadvantages. The main advantage is the ease and speed of execution, and heat sealing of the edges. Its disadvantage, the need to keep the pulse for a good layout, and the stale air released by the welder. It would be necessary add a small extractor pump located at the tip of the welder.

It is also possible to cut by scissors or by cuttern, which eliminates the problem of stale air. Other builders, even not-professionals, use plotter laser computer guided,,,

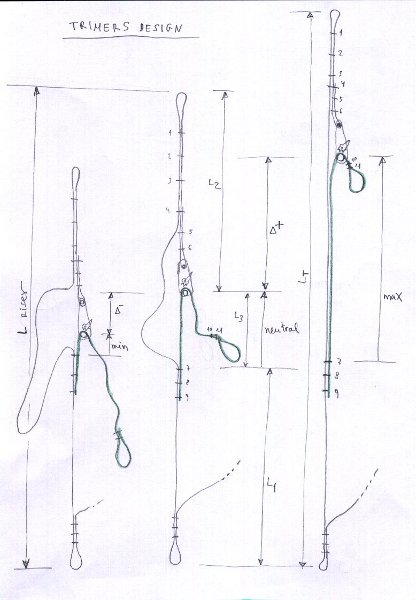

We planned to do the first test triming adjustment in the Berga training ramp or Organyà in october...

The cutting of the ripstop has been done with a soldering iron of 30W for electronics, with a sharp edge knife-shaped. We put the ripstop, above the template of the panels or ribs (template formed by the junction of A3 size sheets). The tracing was performed with ease by the transparency of the ripstop.The method has its advantages and disadvantages. The main advantage is the ease and speed of execution, and heat sealing of the edges. Its disadvantage, the need to keep the pulse for a good layout, and the stale air released by the welder. It would be necessary add a small extractor pump located at the tip of the welder.

It is also possible to cut by scissors or by cuttern, which eliminates the problem of stale air. Other builders, even not-professionals, use plotter laser computer guided,,,

We planned to do the first test triming adjustment in the Berga training ramp or Organyà in october...

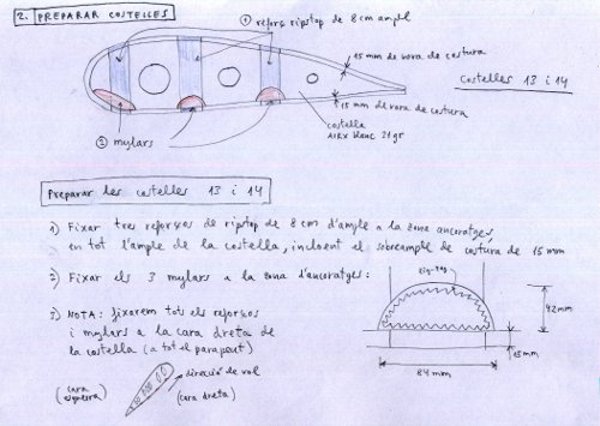

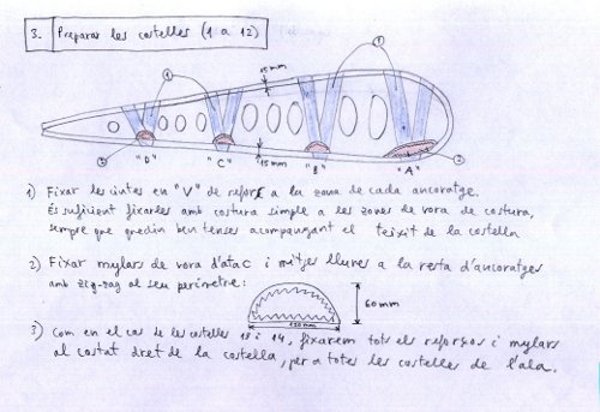

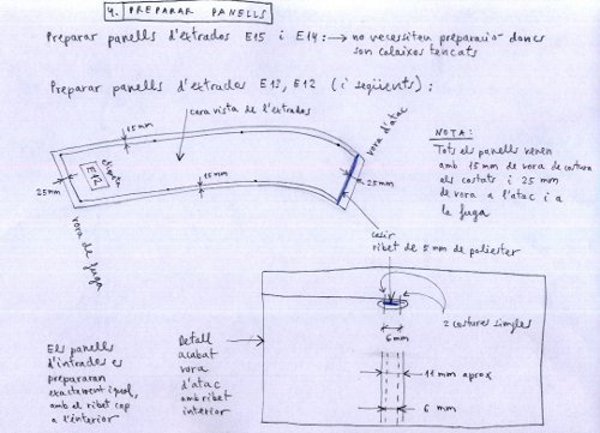

2. Assembly notes