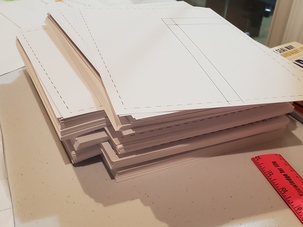

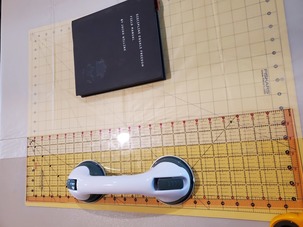

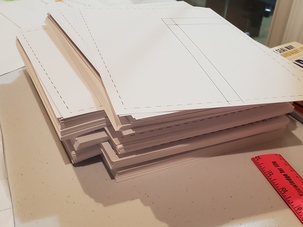

01. Portion of the 1123 pages to

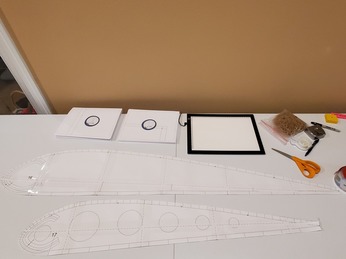

print pattern

|

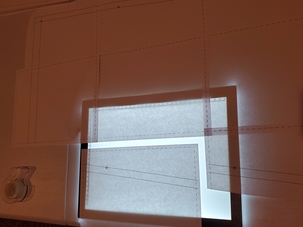

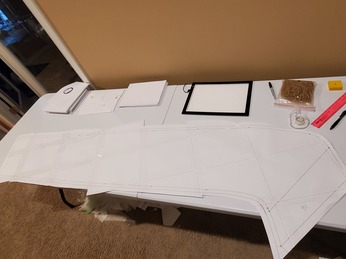

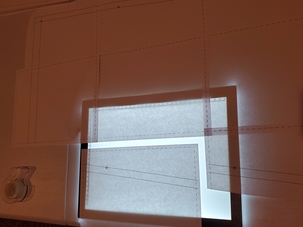

02. Putting pattern together

|

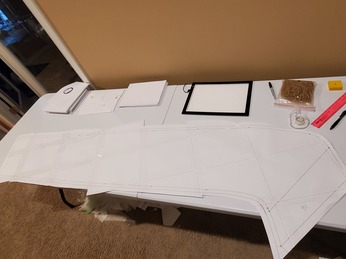

03. Completed panel pattern

|

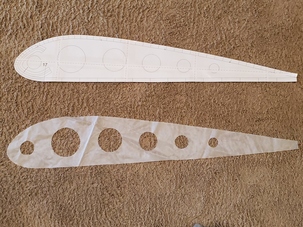

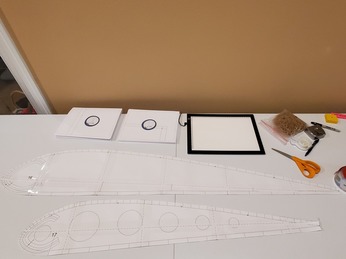

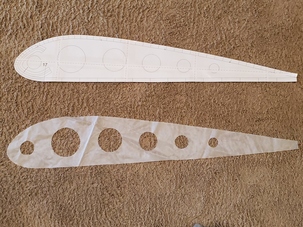

04. Completed rib patterns

|

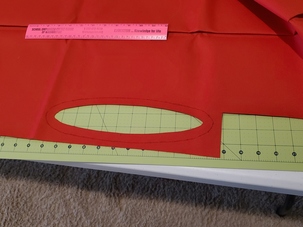

05. Rib 17 fabric cut

|

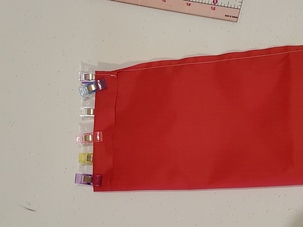

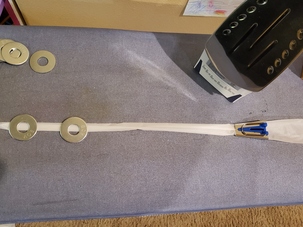

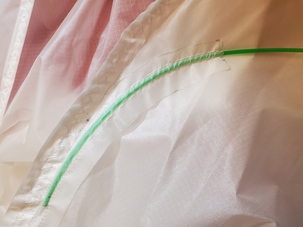

06. Rib 16 with rod pocket and

attachment reinforcements (Ottertex Polyester Ripstop)

|

07. Cutting lower panel

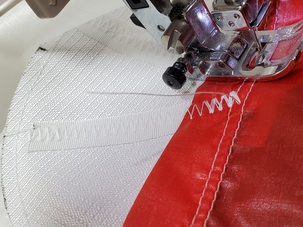

|

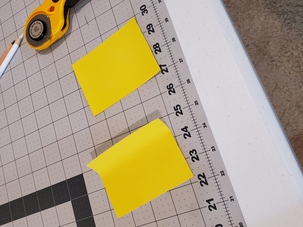

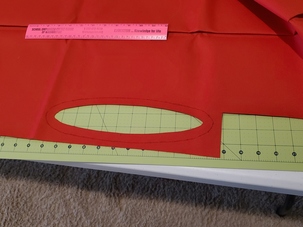

08. Cutting reinforcement

(Ottertex 210d Polyester Canvas) for elliptical inlet

|

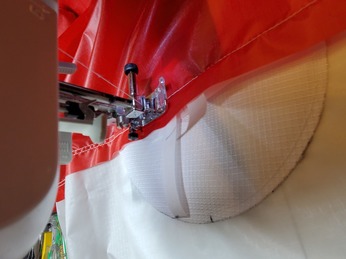

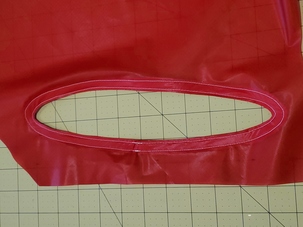

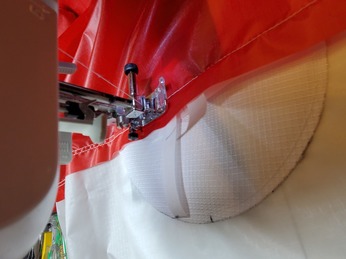

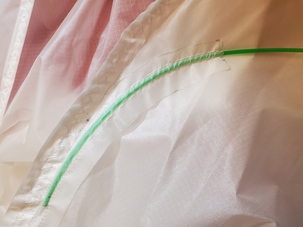

09. Attaching inlet reinforcement

|

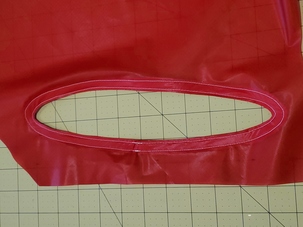

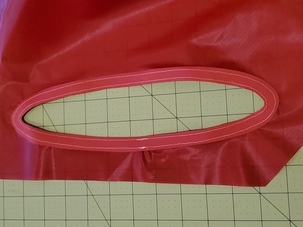

10. Inlet complete front

|

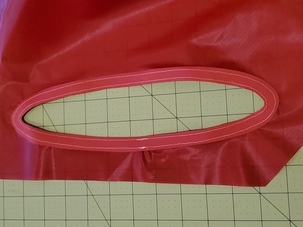

11. Inlet complete back

|

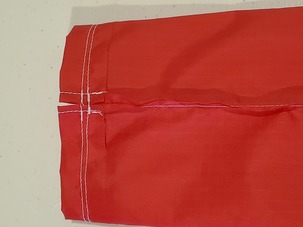

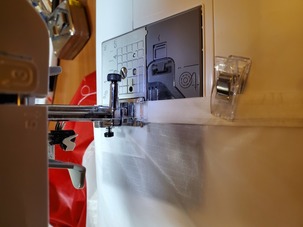

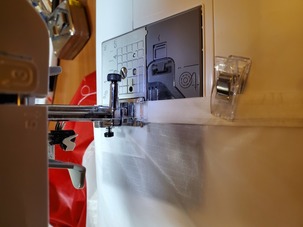

12. Sew upper and lower panel 17

leading edges together

|

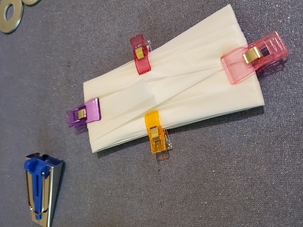

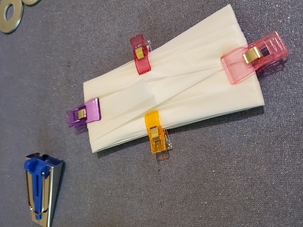

13. Lower panel 17 pinned to rib

16

|

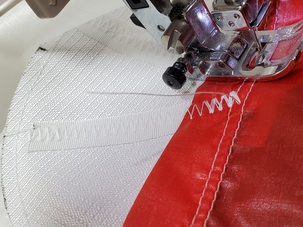

14. Sew lower panel 17 to rib 16

and insert attachment points

|

15. Sew second seam along bottom

of rib 16

|

16. Sew attachment points to rib

16

|

17. Sew upper and lower panel 18

leading edges together

|

18. Fitting reinforcements to

lower panel 18

|

19. Attach reinforcements to

lower panel 18

|

20. Reinforcements on lower

panel 18

|

21. Back of lower panel 18

|

22. Attaching upper and lower

panel 17 and 18 to rib 17

|

23. Rib 18 finished

|

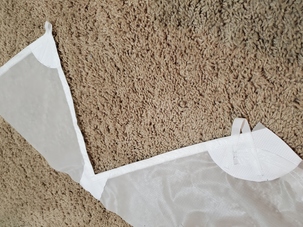

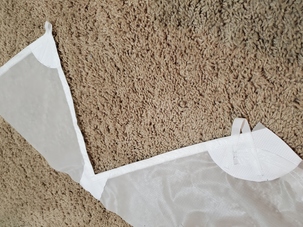

24. Turn upper and lower panel

18 inside out and pin edges together

|

25. Sew along edge, inserting

attachment point as I go

|

26. Sew attachment points down

to reinforcements

|

27. Turn upper and lower panel

18 right side out

|

28. Close up of lower panel 18

|

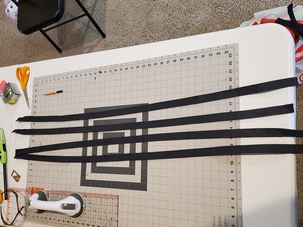

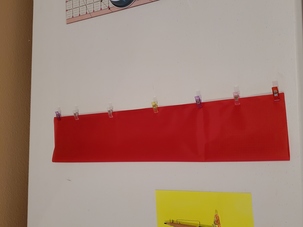

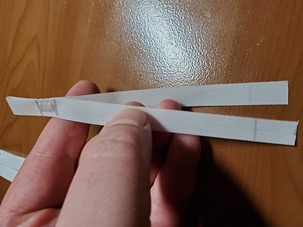

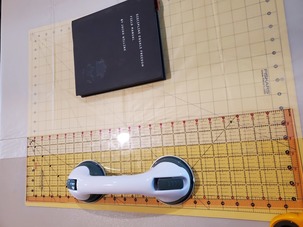

29. Cutting 2 inch strips to

make half inch double-folded bias tape

|

30. Fold strip with bias tape

tool and iron on light setting

|

31. Wrap bias tape around

cardboard for future use

|

32. First sew reinforcements to

rib, then rod pocket, next sew double-bias tape along edges and finally

sew on attachment points

|

33. Sew panels 14 and 15 to rib

15

|

34. Rib 15 completed

|

35. Bottom view of completed

cells 15-18

|

36. Progress pic

|

37. Progress pic

|

38. Progress pic

|

39. All panels done

|

40. All panels done

|

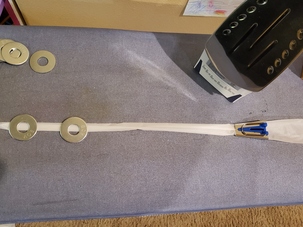

41. Insert nylon rod into rod

pocket

|

42. Close rod pocket

|

43. Finished rod pocket

|

44. All rod pockets done

|

45. All rod pockets done

|

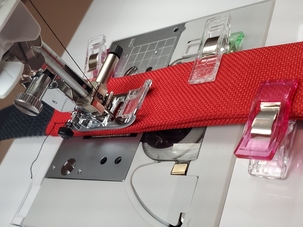

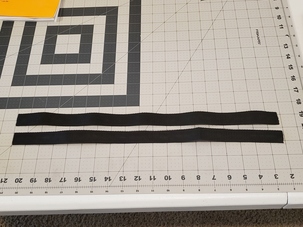

46. Sewing bias tape along

trailing edge

|

47. Sewing bias tape along

trailing edge

|

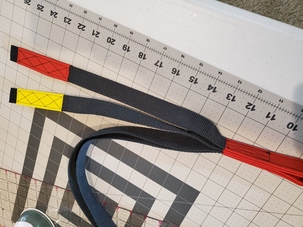

48. Preparing brake attachment

point

|

49. Brake attachment point

clipped onto trailing edge

|

50. Brake attachment point done

|

51. Brake attachment point done

|

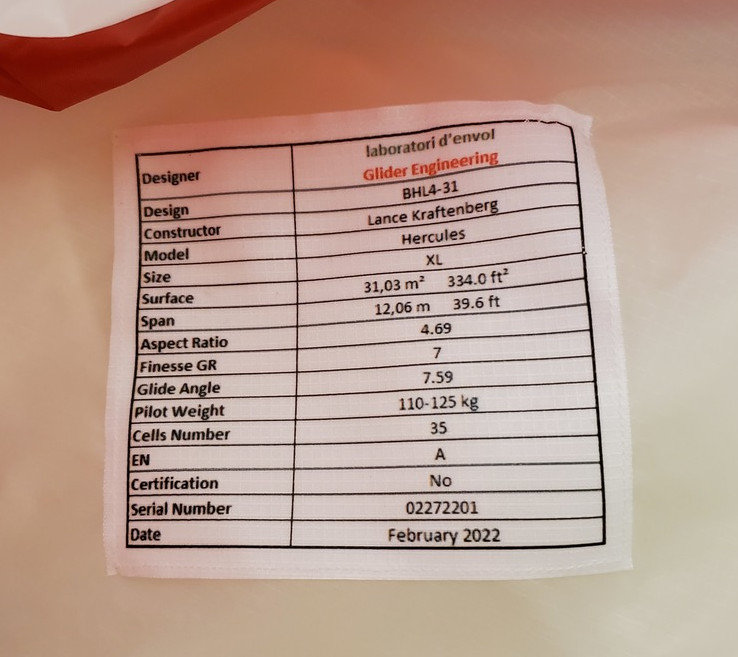

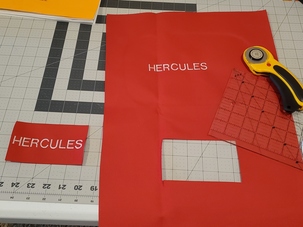

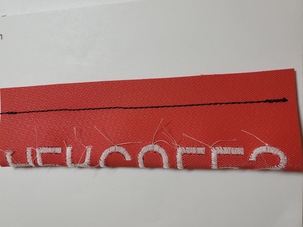

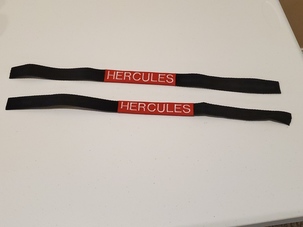

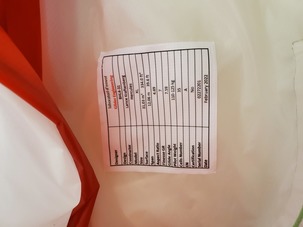

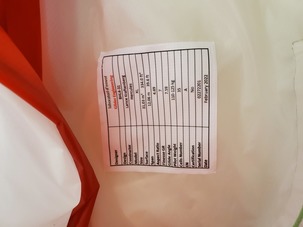

52. Attach information placard

|

53. New stuff sack

|